In the quest for cleaner transportation and reduced greenhouse gas emissions, hydrogen fuel cell vehicles (FCVs) are emerging as a promising solution. These vehicles harness the power of hydrogen, a lightweight, abundant element, to generate electricity on board, producing only water and heat as byproducts. While still in the early stages of mass adoption compared to battery electric vehicles (BEVs), FCVs offer unique advantages that could make them a major player in the sustainable mobility ecosystem.

How Hydrogen Fuel Cell Vehicles Work

Hydrogen fuel cell vehicles operate using a technology known as a proton exchange membrane (PEM) fuel cell. Here’s a simplified breakdown of how it works:

- Hydrogen Storage: Hydrogen gas is stored in high-pressure tanks onboard the vehicle.

- Fuel Cell Stack: Hydrogen enters the fuel cell stack, where it is split into protons and electrons.

- Electricity Generation: The electrons are routed through an external circuit (creating an electric current to power the motor), while protons pass through the membrane.

- Combining with Oxygen: The electrons and protons recombine with oxygen (from the air) at the cathode, forming water vapor—released through the tailpipe.

Unlike internal combustion engines, FCVs produce zero tailpipe emissions other than water vapor, and unlike battery EVs, they can be refueled in minutes.

(Source: https://afdc.energy.gov/vehicles/how-do-fuel-cell-electric-cars-work)

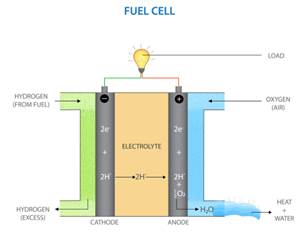

How do PEM fuel cells work?

A proton exchange membrane (PEM) fuel cell, also referred to as a polymer electrolyte membrane fuel cell, produces electricity by undergoing a chemical reaction between hydrogen and oxygen. Here’s a comprehensive description of the process:

The fundamental elements of a PEM fuel cell consist of the anode, cathode, electrolyte, and catalyst. The anode is the electrode where hydrogen gas is introduced. The cathode is the electrode that receives oxygen gas for the electrolysis process. The electrolyte is a membrane that permits the passage of protons but restricts the movement of electrons. The catalyst, typically platinum, is employed to accelerate the reaction at the electrodes.

The process starts with the splitting of hydrogen at the anode. Hydrogen gas is provided to the anode, where, with the assistance of a platinum catalyst, hydrogen molecules are broken down into protons and electrons. The proton-conducting membrane, also known as the electrolyte, enables the movement of protons towards the cathode while preventing the passage of electrons. Because the electrons cannot pass through the electrolyte, they move through an external circuit, generating an electric current that can be utilized to perform tasks like operating an electric motor. Oxygen gas is provided to the cathode. In this scenario, oxygen molecules interact with the protons passing through the electrolyte and the electrons flowing through the external circuit to produce water. The complete chemical reaction in a PEM fuel cell generates water, electricity, and heat. PEM fuel cells offer a clean and efficient energy solution, serving as a sustainable alternative to conventional fossil fuel-based energy systems.

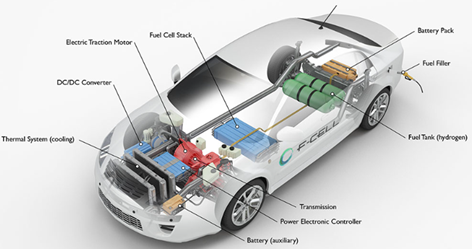

Key Components of a Hydrogen Fuel Cell Electric Car

- Battery (auxiliary): In an electric drive vehicle, the low-voltage auxiliary battery provides electricity to start the car before the traction battery is engaged; it also powers vehicle accessories.

- Battery pack: This high-voltage battery stores energy generated from regenerative braking and provides supplemental power to the electric traction motor.

- DC/DC converter: This device converts higher-voltage DC power from the traction battery pack to the lower-voltage DC power needed to run vehicle accessories and recharge the auxiliary battery.

- Electric traction motor (FCEV): Using power from the fuel cell and the traction battery pack, this motor drives the vehicle’s wheels. Some vehicles use motor generators that perform both the drive and regeneration functions.

- Fuel cell stack: An assembly of individual membrane electrodes that use hydrogen and oxygen to produce electricity.

- Fuel filler: A nozzle from a fuel dispenser attaches to the receptacle on the vehicle to fill the tank.

- Fuel tank (hydrogen): Stores hydrogen gas onboard the vehicle until it’s needed by the fuel cell.

- Power electronics controller (FCEV): This unit manages the flow of electrical energy delivered by the fuel cell and the traction battery, controlling the speed of the electric traction motor and the torque it produces.

- Thermal system (cooling) – (FCEV): This system maintains a proper operating temperature range of the fuel cell, electric motor, power electronics, and other components.

- Transmission (electric): The transmission transfers mechanical power from the electric traction motor to drive the wheels.

Advantages of Hydrogen Fuel Cell Vehicles

Hydrogen FCVs provide several benefits, especially for long-range and heavy-duty applications:

1. Fast Refueling

FCVs can be refueled in 3–5 minutes, similar to gasoline vehicles, which is a significant advantage over battery EVs that often require longer charging times.

2. Long Driving Range

Hydrogen vehicles can travel 300–400+ miles on a single tank, making them suitable for long-distance driving and logistics.

3. Zero Emissions

Hydrogen fuel cells emit only water vapor, offering a clean alternative to fossil fuels and helping reduce urban air pollution.

4. Reduced Battery Dependency

FCVs use smaller batteries, reducing dependence on lithium and other rare earth metals, often associated with mining and geopolitical concerns.

5. High Efficiency

Fuel cell systems are more efficient than internal combustion engines, especially in stop-and-go traffic.

Challenges Facing Hydrogen FCVs

Despite the advantages, hydrogen vehicles face several significant hurdles:

1. Lack of Infrastructure

Hydrogen refueling stations are scarce and expensive to build, limiting the practicality of FCVs outside select regions (e.g., California, Japan, South Korea).

2. High Costs

Fuel cell systems and hydrogen storage tanks are still costly, though prices are falling with advances in manufacturing and scale.

3. Hydrogen Production

Most hydrogen today is produced via steam methane reforming, which emits CO₂. For FCVs to be truly green, hydrogen must come from renewable sources like electrolysis powered by wind or solar.

4. Public Awareness and Acceptance

Compared to battery EVs, FCVs suffer from lower public familiarity, slowing adoption and investment.

Key Market Players in Hydrogen FCVs

Several automotive and energy companies are investing in hydrogen fuel cell technology, recognizing its potential in both passenger and commercial vehicle sectors.

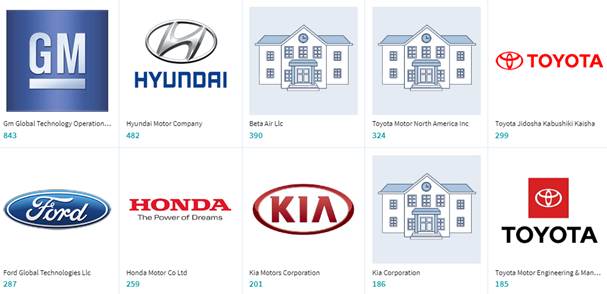

1. Toyota

Toyota is a pioneer in hydrogen mobility. Its flagship FCV, the Toyota Mirai, was among the first commercially available hydrogen cars. Now in its second generation, the Mirai offers over 400 miles of range and serves as a benchmark for the industry. Toyota is also investing in hydrogen-powered trucks in partnership with Hino Motors and exploring fuel cell buses.

2. Hyundai

Hyundai introduced the NEXO, a hydrogen-powered SUV with a sleek design and a range of around 380 miles. The company is also pushing hydrogen solutions in commercial transport, notably with its XCIENT Fuel Cell trucks already operating in Switzerland and other markets.

3. Honda

Honda partnered with GM to develop fuel cell technologies and released the Clarity Fuel Cell, though it has paused production temporarily. Honda remains committed to fuel cells, especially for future applications in larger vehicles and infrastructure.

4. Nikola Motors

Nikola focuses on hydrogen-powered heavy-duty trucks. While it has faced some controversies and leadership changes, the company continues developing hydrogen fuel cell Class 8 trucks and building fueling infrastructure.

5. Ballard Power Systems

Based in Canada, Ballard is a leading developer of PEM fuel cells. Rather than producing vehicles, it supplies fuel cell technology to automakers and industrial partners worldwide, including buses, trucks, trains, and marine vessels.

6. Plug Power

Plug Power is focused on the hydrogen ecosystem—producing, distributing, and using green hydrogen. It powers a large fleet of hydrogen forklifts and is expanding into transportation and stationary power systems.

7. Daimler Truck and Volvo Group

Through a joint venture called Cellcentric, these two heavyweights are co-developing hydrogen fuel cell systems for trucks, aiming for commercialization later this decade. Their efforts reflect growing interest in hydrogen for long-haul trucking, where batteries may fall short.

Patent Landscape and Graphical Exploration

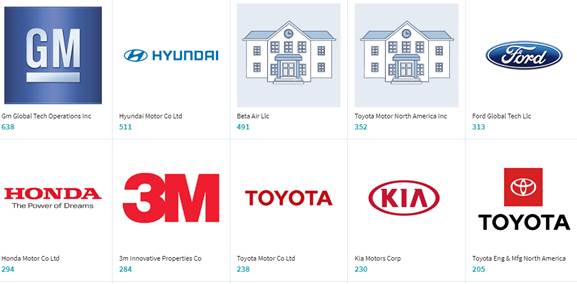

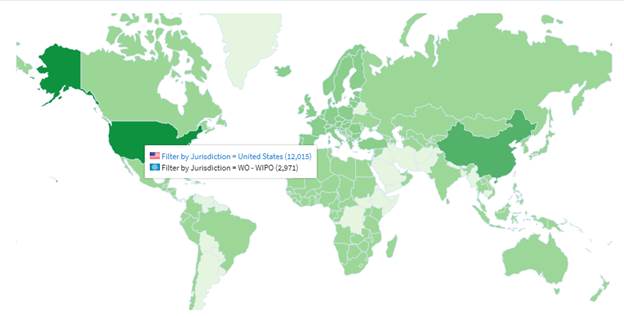

Top Applicants

Solid-State Battery Graphical Analysis (Source: https://www.lens.org/)

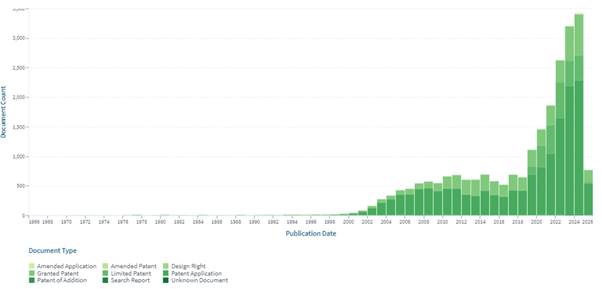

Patent Documents Over Time

Solid-State Battery Graphical Analysis (Source: https://www.lens.org/)

U.S. Leading the Patent Charge

Solid-State Battery Graphical Analysis (Source: https://www.lens.org/)

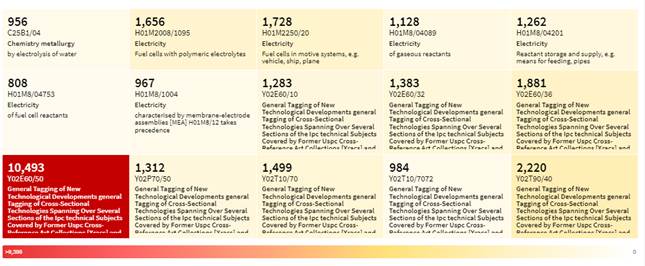

Top CPC Classification Codes

Solid-State Battery Graphical Analysis (Source: https://www.lens.org/)

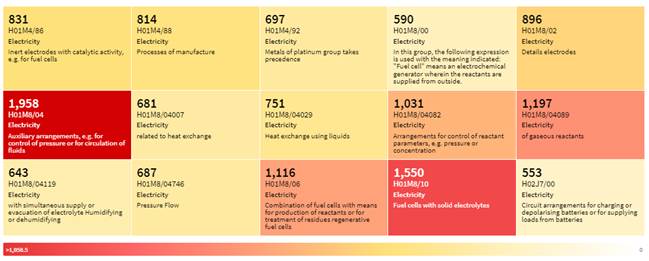

Top IPCR Classification Codes

Solid-State Battery Graphical Analysis (Source: https://www.lens.org/)

Top Owners

Solid-State Battery Graphical Analysis (Source: https://www.lens.org/)

Latest News (Hyundai, Toyota)

Hyundai has revealed its updated Nexo hydrogen SUV. The latest model, which was initially showcased as the concept car at the October event, completely revamps its appearance and incorporates numerous enhancements, such as increased power, extended range, and the unexpected capability to tow. The updated nexo has undergone a significant mechanical upgrade, resulting in an increase in output from the electric motor to 150 kilowatts (approximately 201 horsepower), compared to the previous 120 kilowatts. Torque remains consistent at 350 nm, but Hyundai asserts a faster 0-100 km/h (0-62 mph) acceleration time of 7.8 seconds, a decrease from 9.2 seconds. More relevant for most buyers is the extra range: now targeting over 700 km (435 miles) on the Korean test cycle, thanks to a larger 6.69 kg hydrogen tank (up from 6.33 kg), improved energy density, and better aerodynamic efficiency. The fuel cell stack itself now delivers 110 kw of gross power and benefits from low-temperature improvements, better durability, and something Hyundai calls a ‘wake up’ anti-freezing function – suggesting the system is now better suited to colder climates and real-world winter starts. Additionally, there is a new high-voltage battery with double the power output (80 kw vs. 40 kw), which aids in both performance and energy buffering, particularly during rapid throttle changes or regeneration. European models will also provide towing capacity – up to 1,000 kg. Which is the first time a hydrogen car has officially provided a tow rating, transforming nexo from a mere science experiment with seats into a proper SUV that can perform essential tasks.

Toyota’s hydrogen-powered mirai saloon returns for the 2025 model year with a simplified lineup, some newly standard features, and the same quiet commitment to showing how a fuel cell car should be done. Toyota has included a few previously optional features in the standard lineup for the my25 xle. New standard kit includes a panoramic view monitor (with overhead 360-degree imagery), front and rear parking assist with automatic braking, dual-tone heated mirrors, front footwell illumination, and digital key smartphone access – although the latter requires an active remote connect subscription (obviously, this is 2025) and, naturally, a functioning 4g signal. The car model remains unchanged. It’s still built on Toyota’s GA-L platform – the same one used under the Lexus ls – and retains a rear-wheel-drive layout, with an electric motor mounted at the back delivering smooth, unflustered acceleration. Hydrogen is stored in two high-pressure tanks tucked beneath the rear seats and boot floor, and combined with outside air in a fuel cell stack under the bonnet.